Charcoal Briquette Making Machine - Customized Solution

The whole process takes about 15-25 minutes. Step 3: Biochar is discharged through a manual or automatic water-cooling discharging system. The temperature of charcoal discharged through the automatic discharging system is below 45 degrees Celsius. Step 4: This is charcoal briquette making process. The biomass charcoal is fed into the charcoal

Briquetting Machinery & Equipment - Fercell

From scrap to purpose, harness the power of briquetting to create value from your waste. Benefits of briquette machines include: Volume of input material can be reduced by up to 90%. Improved waste-material handling. Minimised disposal costs. Gaining of storage space. Briquettes can be sold. Even burning briquettes. No additives or binders.

4 Best Compost Machines for Beginner Composters - GreenCitizen

Feb 15, 2024 · These electric food recycling machines, or electric composters, are game-changers, quickly transforming kitchen waste into something useful. For this blog, I have tested four of the best compost machines in the market so that you can make the best purchase decision. 1. Lomi Classic: Best Overall. Check Price at Amazon.

Briquette production and performance evaluation from coal and

Dec 11, 2023 · They concluded that wheat flour as an additive had the lowest moisture content and minimal ash content. Okwu et al. [19] designed a unique integrated hopper briquette machine for the environmentally friendly manufacture of pellet fuels. This one-of-a-kind machine may create billets from the tropics' plentiful biomass.

How Does Briquetting machine Create and Work? - Jay Khodiyar

Applications of Briquettes Making Machine: This high-end machine is ideal for making biofuel using agricultural or forest waste without binder or adhesive. It is widely used for heat generation as it is a perfect replacement of black coal. This powerful machine can make briquettes in cylindrical shapes of sizes from 40mm, 60mm, 70mm, 90mm to 100mm.

Charcoal Briquette Machine | Charcoal Press Machine

Apr 30, 2024 · Features at a Glance. Charcoal briquette machine, also known as a charcoal briquetting machine, is a piece of equipment designed to press charcoal powder into charcoal briquettes. These briquettes can be used as fuel for cooking, heating, and other industrial processes. In the charcoal briquettes production line, this machine is the key machine.

Sawdust briquette machine - Shuliy Machinery

Aug 15, 2023 · The sawdust briquette machine is usually used in the charcoal production line. The biomass materials for briquetting by the sawdust briquette extruder machine should be crushed by the wood crusher first, like bamboo, wood branches, fruit shell, straw (including paddy straw and wheat straw), corn stalk, cotton stem, and so on. These biomass

Briquette presses from WEIMA for wood chips, paper, metal

Briquetting machines made to measure – individual and sustainable. Our briquette presses compact materials such as wood, plastic, paper and cellulose, metal, and biomass (among others) into consistent and valuable briquettes without the use of a binding agent. Depending on the throughput and the intended use of the briquettes, the machines

Briquette Machine - New or Used Briquette Machine for sale

Overall 66% of Wood Briquette Press buyers enquire on only used listings, 34% on new and 13.48% on both new and used Wood Briquette Press items. Buyers usually enquire on 1.81 different Wood Briquette Press classifieds before organising finance. Wood Briquette Press are listed between $2,950 and $35,000, averaging at $24,360.

ECOSTAN | Manufacturers of Complete Biomass Solutions

Chipper Grinder. Range: 1,000-5,000 KG/HR. Hammer Mill. Range: 1,000-7,000 KG/HR. Briquette Machine. Briquette machine is used to make Biomass Briquettes out of any agri/forest waste. (Production range from – 250- 2,500 KG/H) (40MM-100MM Size) Explore Briquette Machine. DualfeedTM Combo Machine.

Briquetting Machines & Applications | www.komarek.com

Our machines can be tailored to your specific applications and are capable of handling sizes as small as 5 lbs (lab size), up to 60 tons (production-machine size) per hour. Key features of KOMAREK briquetting, compaction and granulation machines: Horizontal and vertical feed for screw or gravity feed options. Custom sizes and shapes for pockets.

A TRAINER’S GUIDE FOR MAKING FUEL BRIQUETTES

Use usual decomposing procedures but do not add soil. The material should not decompose into compost fertilizer, about 4 weeks maximum. Make successive heaps of 50cm high x 1metre wide x 5metres long rows to avoid missing what to briquette Dry decomposed material and store safely to save pounding time and trouble.

Charcoal Briquette Making Machine - Customize Briquette

Components and Functions of Charcoal Briquette Machine: After mixing, feeding, and grinding, the needed charcoal powder for making briquettes is made. Then, use the molding machine to make kinds of charcoal briquettes. The whole charcoal briquette making process replaces the manual making of powder and manual preparation of raw materials.

Woodgen Fuel Bricks | Environmentally friendly fuel

Our briquettes reach a high temperature, burn longer and are a cleaner burn, producing less ash. Woodgen is also convenient easy to handle, due to our low moisture content it must be stored in a dry environment to avoid absorbing the moisture we have carefully removed. Buy Online. Briquette Specifications. Size of briquette 15cm x 10cm x 6cm.

Wood Briquetting Machines - RUF Briquetting Systems

A RUF wood briquetting press starts generating value on day one. RUF wood briquette systems: Pay for themselves in less than 18 months. Are engineered for automatic, 24-hour operation with low horsepower. Are compact and integrate easily into existing systems.

-

Automated Egg Harvester: BLJD-Z7III Bolong automatic egg collection systems are suitable for egg collection in chicken farms. Bolong automatic egg collection systems improve the efficiency of collecting eggs. Bolong a...

Automated Egg Harvester: BLJD-Z7III Bolong automatic egg collection systems are suitable for egg collection in chicken farms. Bolong automatic egg collection systems improve the efficiency of collecting eggs. Bolong a... -

Automated Egg Harvester: BLJD-BD2+ Bolong automatic egg collection systems are suitable for egg collection in chicken farms. Bolong automatic egg collection systems improve the efficiency of collecting eggs. Bolong a...

Automated Egg Harvester: BLJD-BD2+ Bolong automatic egg collection systems are suitable for egg collection in chicken farms. Bolong automatic egg collection systems improve the efficiency of collecting eggs. Bolong a... -

Automated Egg Harvester: BLJD-BD2 Bolong automatic egg collection systems are suitable for egg collection in chicken farms. Bolong automatic egg collection systems improve the efficiency of collecting eggs. Bolong a...

Automated Egg Harvester: BLJD-BD2 Bolong automatic egg collection systems are suitable for egg collection in chicken farms. Bolong automatic egg collection systems improve the efficiency of collecting eggs. Bolong a... -

Automated Egg Harvester: BLJD-BS3+ Bolong automatic egg collection systems are suitable for egg collection in chicken farms. Bolong automatic egg collection systems improve the efficiency of collecting eggs. Bolong au...

Automated Egg Harvester: BLJD-BS3+ Bolong automatic egg collection systems are suitable for egg collection in chicken farms. Bolong automatic egg collection systems improve the efficiency of collecting eggs. Bolong au... -

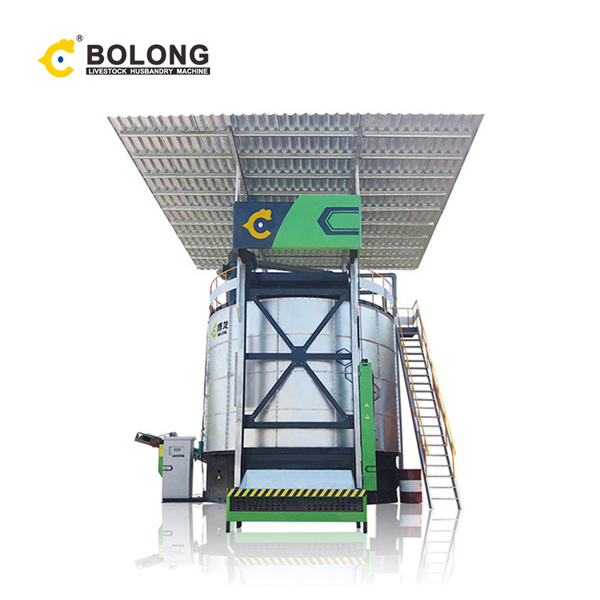

Manure Fertilizer Fermentation Tank -11FFG-280

Manure Fertilizer Fermentation Tank -11FFG-280For fermentation of animal manure into organic fertilizer,with a daily output of 8-12m³ organic fertilizer

-

Manure Fertilizer Fermentation Tank -11FFG-160

Manure Fertilizer Fermentation Tank -11FFG-160For fermentation of animal manure into organic fertilizer,with a daily output of 5-7.5m³ organic fertilizer

-

Manure Fertilizer Fermentation Tank -11FFG-90

Manure Fertilizer Fermentation Tank -11FFG-90For fermentation of animal manure into organic fertilizer,with a daily output of 3-4.5m³ organic fertilizer

-

Manure Fertilizer Fermentation Tank -11FFG-102

Manure Fertilizer Fermentation Tank -11FFG-102For fermentation of animal manure into organic fertilizer,with a daily output of 4-5m³ organic fertilizer

-

Say Goodbye to Waste Challenges: Bolong Commercial Compost Equipment

Say Goodbye to Waste Challenges: Bolong Commercial Compost EquipmentSolve livestock waste troubles with Bolong commercial compost equipment! 30 years of expertise, high-temp fermentation, 360° support—turn waste into premium fertilizer for higher farm profits.

-

7-Day Chicken Manure to Resources via Large Scale Composting Machines

7-Day Chicken Manure to Resources via Large Scale Composting MachinesWhy struggle with chicken manure disposal? Bolong large scale composting machines turn it into resources in 7 days. 99% sterilization, IoT control, 40% energy saving. Fits laying/broiler manure. Boost efficiency & profits.

-

Bolong Invites You to AHCAB 2026 Low Power Composting for Bangladeshi Farms

Bolong Invites You to AHCAB 2026 Low Power Composting for Bangladeshi FarmsBolong at AHCAB 2026: Low-power industrial composting machines for Bangladesh. Heat exchange tech cuts costs, boosts profits. Visit Booth 155-156-157 for tailored solutions.

-

Transform Waste to Fertilizer in 7 Days: Organic Composting Machine Guide

Transform Waste to Fertilizer in 7 Days: Organic Composting Machine GuideBolong’s technical analysis of composting machines reveals the science behind converting chicken manure into high-quality organic fertilizer. Discover how high-temperature aerobic fermentation systems deliver safe, efficient processing in just 7 days, driving sustainable agriculture.

-

Bolong 2025 Abu Dhabi VIV MEA Recap,Internationally Recognized

Bolong 2025 Abu Dhabi VIV MEA Recap,Internationally RecognizedVIV MEA 2025 Success! Bolong large scale composting machine is the “”pivotal technological hub”” for a closed-loop resource system. Achieve 7-day maturity, environmental compliance, and protect air/water/soil. Learn why global experts choose Bolong.

-

Guide: Turn Farm Manure into Profit with Large Scale Composting Machines

Guide: Turn Farm Manure into Profit with Large Scale Composting MachinesHigh manure costs & regulations? Large scale composting machines (Bolong) turn waste profitable—7-day aerobic compost, cut costs, avoid fines. Case proves compliance. Contact for custom configs.

English

English

中文简体

中文简体